INFINITE AUTOMATION CO ., LIMITED

Infinite Automation Co., Ltd was established in 2006 and is now one

of the world's leading suppliers of high-quality AI and SMT Factory

Automation Machines, Equipment, and Production Solution Products.

As an export company, we always aim to provide high-quality

products to customers in Asia, America, and Europe at very

competitive prices. With the long-term support and help of global

customers, we are able to expand our business in a short period of

time.

Our factory is located in Fuyong, China, with 800 square meters of

facilities, a two-story warehouse building. Our company focuses on

sales and distribution of Factory Automation Machines and

Equipment.

Our factory is consisted of about 40 engineers and professional

staff that handle R&D, Production, Quality Assurance, and Sales

and Marketing Team that ensures that all products we deliver are

well inspected and pass high-quality standards.

Our Product Line:

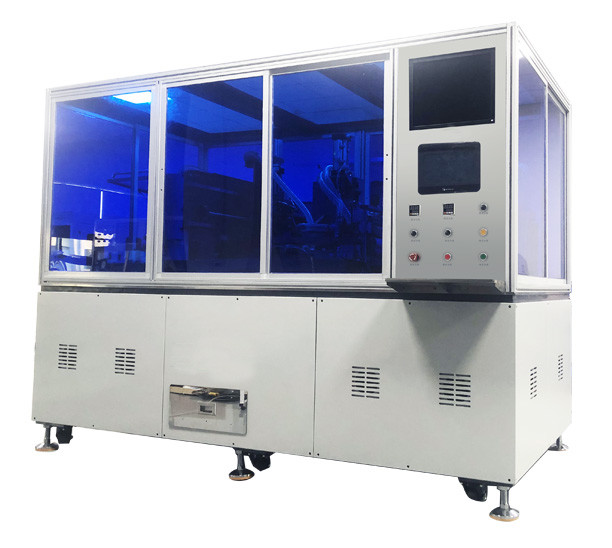

New and Pre-Owned Solder Paste Printing Machine

New and Pre-owned SMT Chip Mounter

SMT / PCBA Cleaning Machines and Equipment

SMT / PCBA Production Machineries and Equipment

SMT Machine Replacement Parts, Component Feeders, Feeder Parts

Production Line Consumables, ESD Products, Splice Tapes, and Tools,

etc.

Infinite Automation Co., Ltd. is now China's leading provider of

innovative SMT Factory Automation and Solution Products. We have

achieved this because of the continuous support provided by our

valued clients, and business partners.

We will ensure that we will continue to provide high-quality

products at competitive prices. We will also keep our communication

open and always listen to our customer's needs and help our clients

reach their goals.